The Transformation of Medical Device Companies

There was a time not that long ago when being a successful orthopedic medical device company meant being excellent at manufacturing parts. You designed reliable products, ensured quality, managed inventory, and delivered at scale. That was the business, and for years, it worked.

But the landscape is shifting quickly. Today, the companies leading the orthopedic sector aren’t just defined by what they produce; they’re defined by how they produce it, and how that product connects to a larger digital and clinical ecosystem. In other words, they’re moving from being traditional manufacturers to technology-enabled platform companies.

This shift is being driven by a mix of market forces meeting emerging technological possibilities. On one hand, healthcare systems are demanding more value: better outcomes, lower costs, and improved patient experiences. On the other hand, advancements in technology are making it possible to deliver on those demands in new and exciting ways.

The result? A redefinition of what it means to be an orthopedic medical device company.

The Power of Integration

At the center of this transformation is a growing emphasis on integration. No longer is it enough to develop an implant and send it off to a hospital. Today’s orthopedic innovators are building platforms, also known as systems of digital tools, services, and manufacturing capabilities that support the full journey of care, from planning and procedure to recovery and follow-ups.

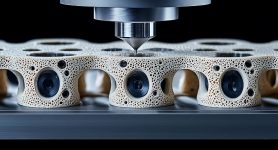

3D technologies are at the heart of this new model. In pre-operative planning, 3D visualization allows for a deeper, more intuitive understanding of a given patient’s anatomy. Surgeons can rehearse procedures virtually, simulate different implant placements, and make more informed decisions before ever entering the operating room. This not only improves surgical accuracy, it builds confidence and improves communication between the care team and the patient.

During the surgery itself, 3D technologies enable access to patient-specific instrumentation and custom guides that make procedures more efficient and precise.

The power of 3D visualization and 3D printing lies in how it enables customization and innovation. Complex lattice structures that promote bone ingrowth, lightweight geometries that reduce fatigue, and entirely personalized implants are now possible thanks to additive manufacturing.

Even more importantly, these products can be integrated into a broader platform strategy, enabling rapid iteration and responsiveness to clinical feedback.

This kind of flexibility would have been unimaginable in the past. Traditional manufacturing lines were rigid and expensive to change. Today, with digital workflows and additive manufacturing capabilities, iteration happens faster and smarter. We’re not just speeding up processes; we’re closing the loop between engineering and clinical outcomes.

The Intelligence Feedback Loop

That feedback loop is one of the most important advantages of moving to a platform model. Imaging feeds into surgical planning. Planning influences implant design. Real-world surgical outcomes flow back to R&D for refinement. Each component—digital or physical—adds intelligence to the next. Over time, this creates a learning system that becomes smarter and more effective with each procedure.

Of course, this transformation doesn’t come without challenges. Becoming a platform company means stepping into areas that traditionally haven’t belonged to manufacturing: software development, cloud infrastructure, cybersecurity, and user experience design, to name just a few. It also means building new kinds of teams: bringing together clinicians, data scientists, engineers, and regulatory experts to work in harmony.

Integration remains one of the biggest hurdles in this platform-driven shift. Even the most advanced tools lose their impact if they don’t fit naturally into existing clinical workflows. Technology, no matter how powerful, must work for the people using it, not the other way around.

That’s why the most successful companies are those that stay close to their end users’ needs: Not just the surgeon at the center of the procedure, but the entire care team supporting the patient journey. From surgical planning to recovery tracking, every touchpoint matters. Solutions that are intuitive, interoperable, and built with real-world clinical needs in mind are the ones that ultimately drive adoption and impact.

Fortunately, companies don’t have to start from scratch. There are robust, off-the-shelf platforms and medical-specific digital solutions already available and designed to integrate seamlessly into clinical environments. These tools offer a strong foundation, enabling medical device companies to accelerate their digital transformation without reinventing the wheel.

What’s more, medical-specific digital solutions are ripe for streamlining and automation, which not only increases efficiency but also can reduce human error, thus ensuring high quality while minimizing cost. Integrated seamlessly within these digital solutions are “hooks” requiring human oversight and review. The potential impact on strained healthcare networks, overworked employees, and understaffed departments is significant. Some of the industry’s most exciting innovations come from organizations that are leaning into this AI-enabled, integrated approach. They are building on proven digital infrastructures to deliver connected, clinician-friendly ecosystems. Cloud-based platforms now allow surgeons to plan cases collaboratively, order custom implants, and review post-operative data, all in one centralized environment. The result is a more streamlined, informed, and adaptive surgical experience that benefits both clinicians and patients alike.

This transformation also brings a meaningful shift for the medical device sales representative. In a platform model, sales reps are no longer just product experts; they become strategic partners. With access to rich planning tools and clinical data, they’re empowered to offer more value to surgeons than ever before—helping with pre-op planning, troubleshooting cases, and supporting post-op review. This data-driven insight enables them to build stronger relationships with clinicians and contribute more directly to better outcomes. It’s a shift from a transactional to consultative approach and it’s creating a more informed, collaborative environment for everyone involved.

User-Centered Solutions

Let’s not forget the patient. In this new model, patients are more than just recipients of devices; they’re active participants in their care journey. Personalized educational tools, 3D prints of tumors and defects, progress dashboards, and even AR/VR visualizations of their upcoming procedures are empowering patients in ways we haven’t seen before. This kind of engagement isn’t just nice to have, it can directly improve satisfaction and outcomes.

So what does all this mean for the future of orthopedic care?

It means we’re entering a new era where technology and manufacturing aren’t separate, they’re intertwined, where success isn’t measured solely by product quality but by the value the platform delivers across the continuum of care. Where 3D technologies don’t just enable production, they empower personalization, precision, and progress.

Companies that can bring all of this together—the craftsmanship of traditional implant design, the agility of additive manufacturing, and the intelligence of digital platforms—will be the ones that shape the future of the industry.

We’re not just building implants anymore. We’re building ecosystems. We’re building experiences. And ultimately, we’re building a more connected, more personalized, and more effective future for orthopedic care—one precisely (3D) printed, insight-driven solution at a time.

MORE FROM THIS AUTHOR—Navigating 3D Technologies: A Success Blueprint for Medical Device Start-Ups

Nora Toure is a recognized leader in the Additive Manufacturing (AM) industry. She currently serves as the director of medical software sales for North America at Materialise, where she empowers healthcare providers and businesses to harness the potential of 3D planning and printing in medical applications. She is also the founder of Women in 3D Printing, a global organization committed to advancing diversity and inclusion within the 3D printing community.